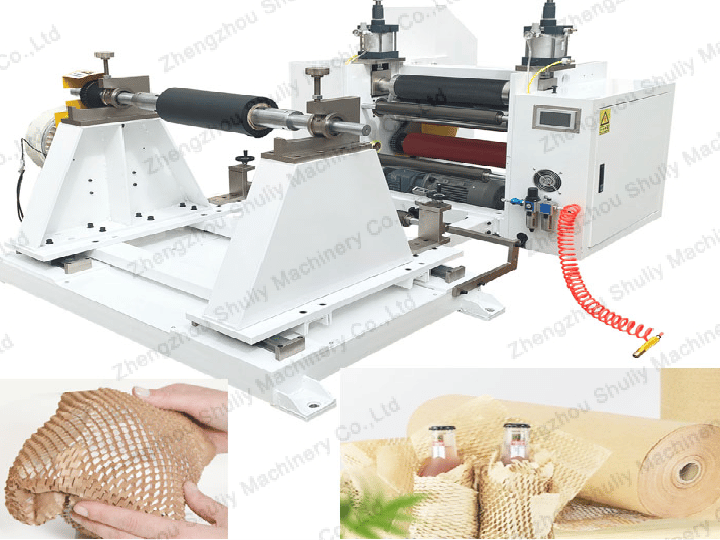

This honeycomb Kraft paper-making machine can automatically cut kraft paper, honeycomb wrapping paper is a high-quality kraft paper packaging material, which is widely used in packaging due to its environmental friendliness. It can play a buffering role and reduce the amount of plastic used.

Introduction of honeycomb Kraft paper

The honeycomb paper is modeled after the structure of the honeycomb. Honeycomb paper is also called geami paper, The honeycomb structure of the bee is very delicate, and it is a regular hexagon with the least amount of materials and is very stable. Because its stable structure has long been used in aerospace engineering, the honeycomb Kraft paper processing machine is also designed using the unique structure of the honeycomb. After being cut by a honeycomb paper processing machine, the kraft paper will form uniform honeycomb-shaped pores. Used in the packaging industry. Also used for packaging is cardboard recycling, and cardboard shredders are generally used for cardboard shredders.

Why is geami paper called an environmentally friendly material?

According to experiments, the honeycomb paper can be completely degraded after 120 days. In recent years, more and more countries have realized the harm of plastics to the environment, and they have been looking for alternatives to plastics. The geami paper is harmless to the environment during the explanation process, and the degradation time required is shorter.

Honeycomb paper making machine application range

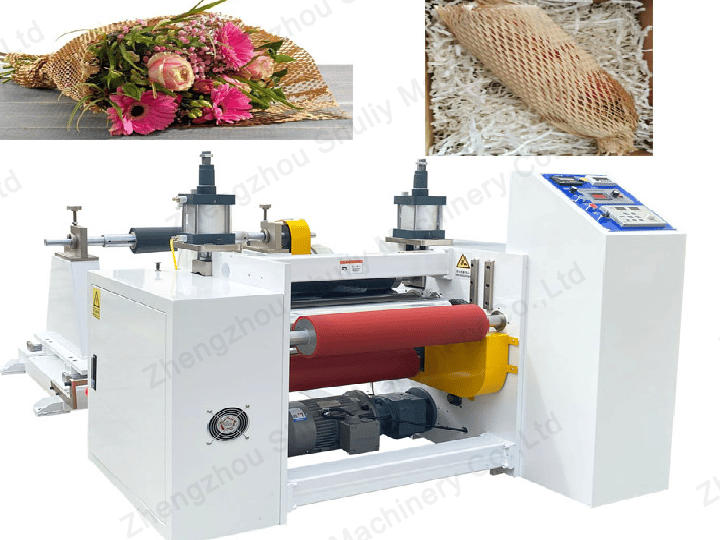

Honeycomb paper is an eco-friendly and cost-effective alternative to plastic bubble wrap cushioning. It stretches easily, is softer and more flexible, and when used as a packaging material, provides cushioning protection without scratching the surface of items. The finished product of the honeycomb paper-making machine can be used to pack fruits, flowers, ceramics, glassware, metal products, glass products, electronic products, handicrafts, gifts, stationery, daily necessities, etc.

Is the cushioning effect of honeycomb wrapping paper good?

The geami paper is interlaced with multiple layers of honeycomb, which not only has a good buffer protection effect but also is not easy to slide. The packaging does not need additional tape and rope to fix it. As a packaging product, it is very simple and convenient to use. And honeycomb paper packaging beauty, gifts can be bundled with ribbons, hemp rope decoration, can enhance the appearance of the package, enhance the customer’s unpacking experience.

Honeycomb Kraft paper making machine finished product advantages

1. Lightweight and low cost

Compared with other plastic bubble wrapping materials, honeycomb wrapping paper is small in size and compact in structure, which can save transportation costs.

2. Perfect cushioning

Geami paper can provide good cushioning and good protection for fragile items. Honeycomb paper has a unique structure, which is elastic and can absorb external pressure.

3. Environmentally friendly

Compared to other plastic wrapping films, honeycomb wrapping paper is made from recyclable kraft paper. It is a biodegradable and environmentally friendly packaging alternative.

Honeycomb paper making machine finished product function

Before the honeycomb kraft paper cutting machine is formed, the appearance of honeycomb mesh wrapping paper is almost the same as that of ordinary cylindrical kraft paper. After being processed by the honeycomb paper processing machine, the length of the paper can be extended by 1.4-1.7 times. Using its physical structure and material properties, it can provide excellent cushioning and shock absorption for packaged goods and prevent scratches. With reasonable coverage, honeycomb pads can provide excellent shock absorption for fragile items, comparable to PE plastic airbags and foam products.

How to use the honeycomb paper making machine?

In the process of kraft paper processing, the raw material to be processed is the paper in the bundle. After being cut by the honeycomb paper processing machine, it is still paper in rolls. When it is not stretched, there is no difference in appearance, which can make the manufacturer Save inventory space. Put the roll of paper on the machine, turn on the switch and the machine can start production automatically.

Honehoneycomb Kraft paper making machine parameters

| Machine model | SL-500 |

| Web working width | 600mm |

| Mould effective width | 500mm |

| Unwinding diameter | 0-1200mm |

| Unwinding stand weight | 1Ton(can make bigger) |

| Unwinding shaft | 3-inch inflatable air shaft |

| Rewinding shaft | 1inch/1.5inch/2inch/3inch |

| Machine size | 2620*1640*1160mm(LWH) |

| Machine weight | 1000Kgs |

| Power supply | 380V 3 Phases 5 wires |

| Air pressure | 6-8kg/c Square meter |

| Max. diameter of finished roll | 300mm |

| Cutting Speed | 0-80m/min |

| Total power | 6kw |

The width of the paper roll that can be placed by the honeycomb paper processing machine is about 500mm, the diameter of the paper roll can be 0-1200mm, and the load-bearing capacity of the machine is about 1 ton, which can reduce the frequency of changing paper rolls and reduce the workload.

Honeycomb paper making machine features

1. This machine is suitable for die-cutting honeycomb paper, wrapping paper, shock-absorbing paper, kraft paper, and fishnet paper.

2. The main motor is equipped with a frequency converter for speed regulation.

3. Unwinding automatic ultrasonic guide controller.

4. Use magnetic powder brake and clutch to control tension.

5. Automatic meter counting device, it will stop automatically after reaching the length you set.

6. Pneumatic cylinder controls the cutting die up and down.

Geami paper making machine installation precautions

(1) The operator should read the manual carefully before operation.

(2) Please check the stability of the four feet of the machine. Whether the fuselage has a ground wire.

(3) The machine should be installed in a dry and ventilated place, and the surrounding objects should be at least 2m away from the machine.

(4) Reliably connect the safety grounding end of the machine to the grounding protection wire, and the joint must be fastened.

(5) Honeycomb Kraft paper-making machine must be operated by professionals.

(6) Connect the wires between the machine and the unwinding frame according to the color, and install the deviation detection device.