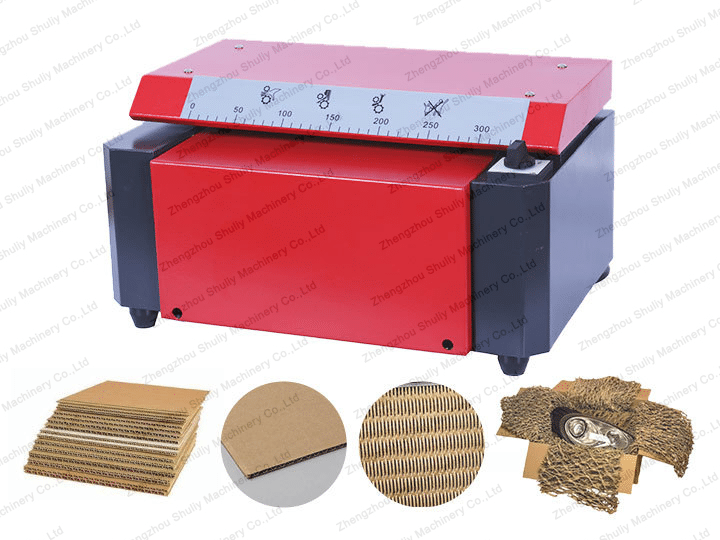

The corrugated paper shredder can shred the carton and make it into a net or strip structure. As a filler for precision instruments and fragile items. It avoids the waste of carton resources and avoids the situation of dealing with waste cartons. We have clients who sell small appliances, handicrafts, and liquor. Corrugated machines are suitable for the packaging of various products.

Paper recycling industry knowledge

Garbage sorting is good for recycling, but is all paper recyclable? Let’s first understand the production process of recycled paper. First, the recycled paper is broken, decolorized, pulped, and then produced by ink separation, pressing, and molding. The process is cumbersome, and some toilet paper, kitchen paper, etc. cannot be recycled all at once, because the cost of cleaning and transportation is high.

Corrugated paper, which is used to make cartons, is often used in product packaging. This type of paper can be used without going through a complicated recycling process. The reticulated paper can be produced by the Corrugated paper shredder, which is used to make the packaging of precision instruments.

Corrugated paper shredder produces paper shapes

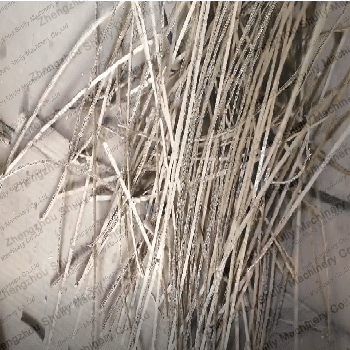

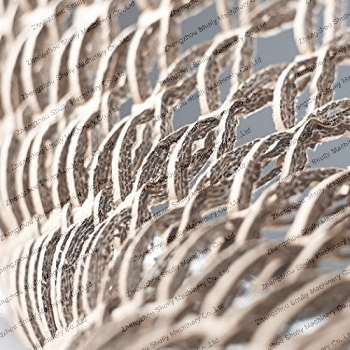

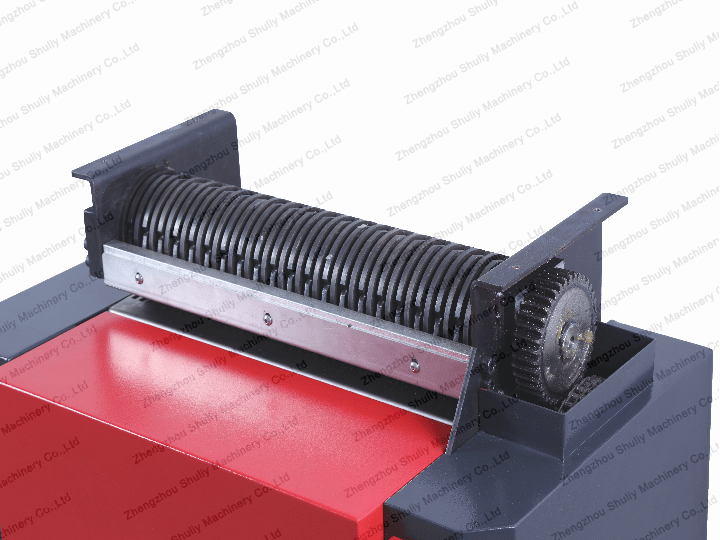

Corrugating machines can break cartons into webs, or strips. The knives used in the production of the two are different, and we can customize them according to your production needs. If you want to produce two types of packing fillers, you can buy two sets of knives and only need to change the knives.

strip-cardboard-paper

reticulated-cardboard

Corrugated paper shredder size

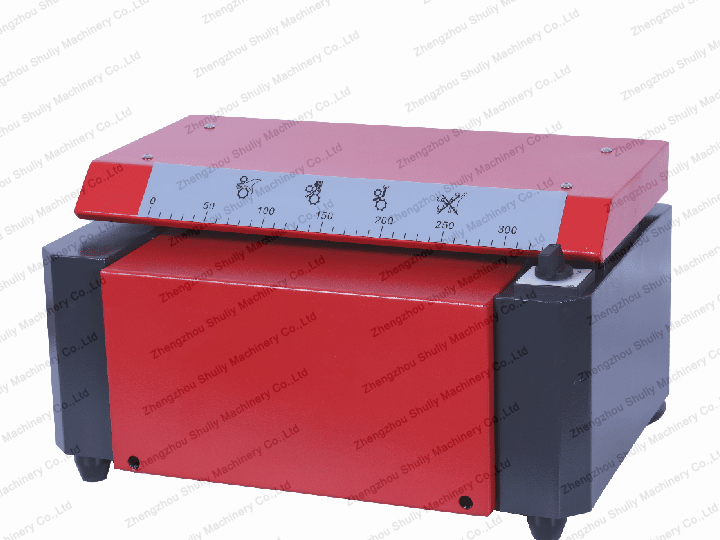

This corrugated paper bulking machine is the smallest model, SL-255 means that the maximum width of the cardboard that the machine can process is 255mm, and a machine is a desktop machine, which can be placed on the desk, which is relatively small and convenient. In addition to the SL-255, we also have cardboard shredders for the SL-325 and SL-425. You can choose according to the product size of the package.

Cardboard shredding machine parameters

| Carton size | Configure motor power | Shell steel plate specifications: material thickness surface treatment paint | Frame Specifications: Material Thickness | Tool material |

| 565*430*310mm | 0.1KW | Cold plate, 1.5mm, paint | Hot Plate, 3.0mm | Tungsten steel |

In the machine parameter table, the motor power of the machine is 0.1w, and the material of the cutting tool is tungsten steel, which is very strong and durable.

Application of cardboard crushing machine

Valuables Packaging

Precision instrument packaging

Glass product packaging

The machine is mainly used for product packaging. For example, some glass products are easily broken during transportation, or some home appliances are made of plastic, which is easy to bump. A layer of broken mesh carton can be placed inside the carton, and the fluffy paper can play a role in fixing the product in the box. In addition, it can play a buffering role when it receives an external collision.

Precautions for using a corrugated paper shredder

The raw material of the corrugated paper shredder can be a cardboard box with tape, which can be processed directly without removing it, but if it is cardboard with iron dicing, it is best to remove the iron nails to prevent iron damage to the machine tool.

Four advantages of using a cardboard crushing machine

1. Green and environmental protection. The corrugated paper has no pollution in the process of repeated processing and utilization and has achieved recycling.

2. Reduce costs. Whether it is self-produced or sold, or processed and sold, there are objective interests.

3. Waste utilization. The machine uses waste packaging boxes, and the raw materials of the products are simple and easy to obtain.

4. Wide range of uses. The corrugated paper processed by Pengqi can be used as a filler for various products.

Video of corrugated paper shredder

The video shows how to use the corrugated paper bulking machine. The machine has a scale for precise processing. The whole machine only needs one person to complete. Excess cartons are produced, which are automatically cut. In addition, the video also shows some common methods of mesh cartons.